Silicone coated rollers and wheel rubber available for purchase throughout Italy

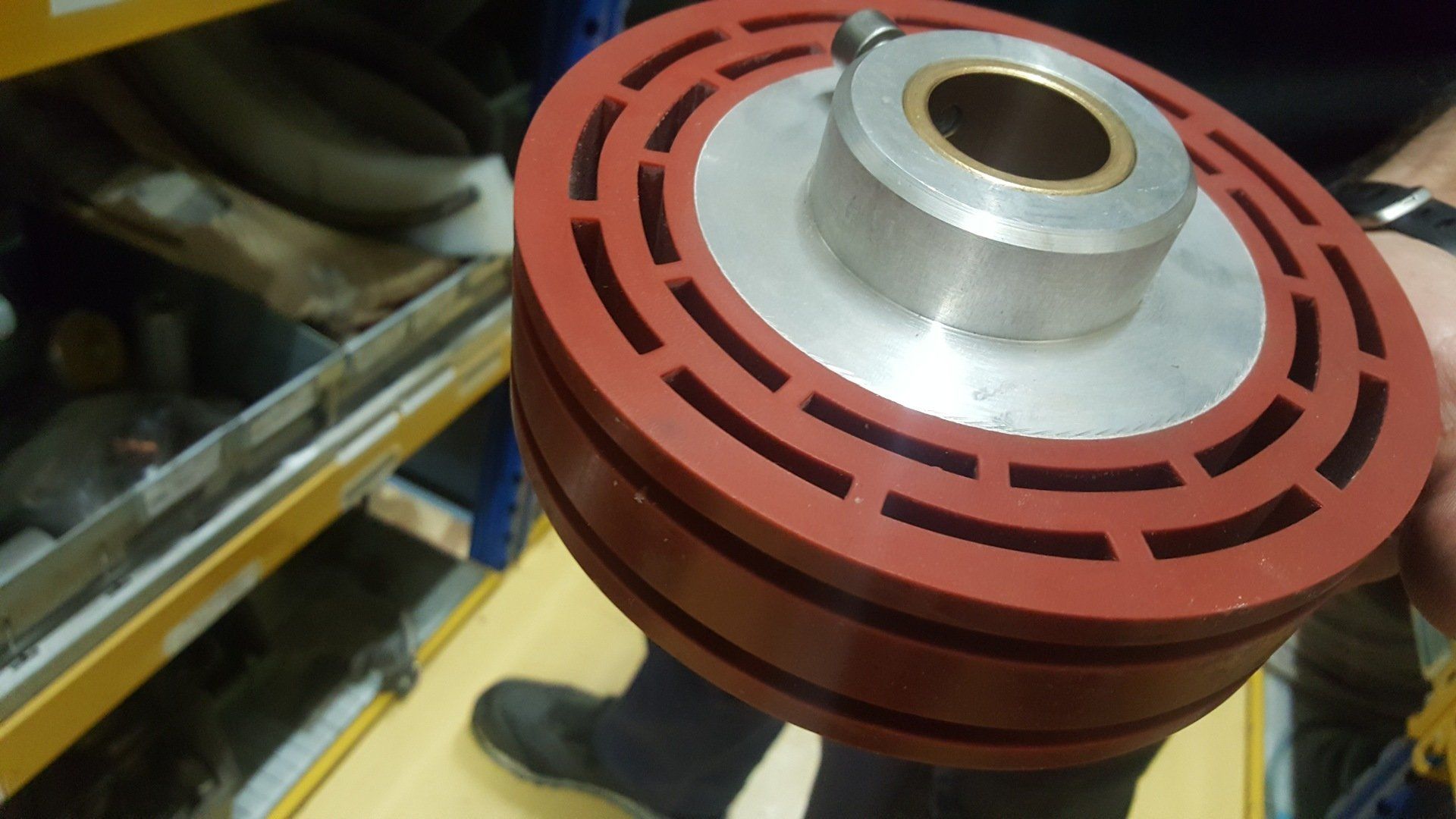

Among the many high-quality services that Lineagomma offers our customers, rubberising rollers and wheels has always received great success. The Parma-based company manufactures rollers coated in silicone, rubber, viton and vulkollan as well as wheels coated in rubber, silicone and polyurethane. It's possible to get a personalised quote just by contacting our offices in Parma about coating wheels and roller with rubber.

Contact us

Manufacturing special custom-made rollers

30 years' experience in customer service

Manufacturing rubber, food and FDA rollers

Rollers for covering rubber and polyurethane wheels

Making antistatic and wear-resistant rollers

Coating rollers and wheels can be done using compounds that have different features:

- wear-resistant;

- oil-resistant;

- chemical-resistant;

- resistant to high temperatures;

Cold stamping, taping and gluing

Both tasks of rubberising and coating can be performed with either hot or cold techniques. In the first case, for example hot, the methods used are moulding and taping.

Grinding and final finishing of the products

After the coating phase, grinding or turning are carried out for the customised finish, depending on the customer's requirements. Here are some examples:

- smooth;

- rounded;

- with longitudinal grooves;

- with transverse grooves;

- with rhombus grooves;

- fish bone.

For more details about manufacturing silicone or viton coated rollers, contact the Lineagomma company's office in Parma.

Get a quote from our specialists

Find us

For more information on silicone coated rollers made by our company, call our technicians now